Taylor Swift, Master of Rebranding

Despite her lyrics claiming otherwise, Taylor Swift can have nice things. Why? She's a master of rebranding. She's able to...

Customer Service Automation: The Ultimate Guide for SMBs

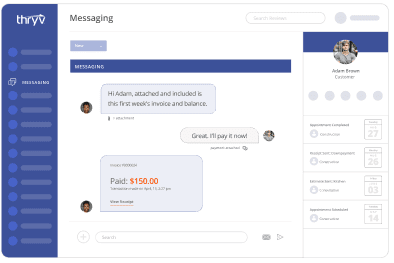

When it comes to customer service, automation is more than just chatbots. Sure, chatbots are all the rage right now,...

AI in Customer Service: Everything Your SMB Needs to Know

“AI in customer service”: That phrase either excites you or scares you as a business owner. The exciting part is...

What is Seasonal Marketing? (+Build a Campaign in 5 Steps)

Like it or not, seasonality impacts every small business. Whether it’s the ebbs and flows of changing seasons or the...

Get more free content to help your business.

A great online presence is essential for your business– how does yours stack up?

Use our free analytics tool to see how your business compares to the competition and find out what customers are saying about you.

Learn how we will use your information

Privacy Notice: I consent to receiving a telephone call and/or electronic promotional and marketing messages from or on behalf of Thryv about its products and services. You can withdraw your consent at any time. You can contact us at [email protected], by opting-out of email marketing directly on our unsubscribe page, or at Thryv, 1155 Volunteer Pkwy, Suite 201, Bristol, TN 37620, USA . For more information on how we handle your personal information, please see our privacy policy.